Flexible Graphite

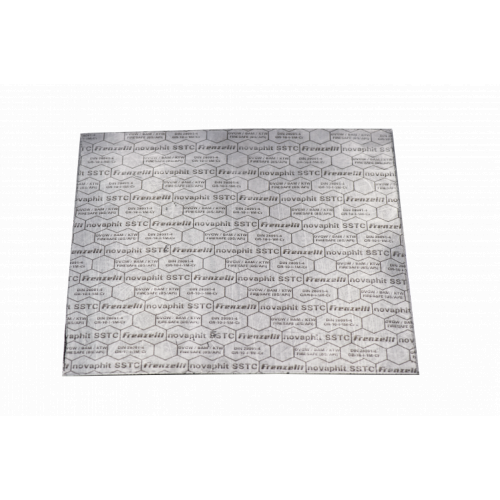

Style 7505 - Novaphit SSTC Flexible Graphite Inserted With Stainless Steel Wire Mesh

Novaphit SSTC is made of high quality, expanded graphite and an expanded metal insert made from acid-proof-stainless steel AISI 304 - 1.4404, mesh (3 mm wide). Under high pressure the expanded graphite particles are compressed to films without adding any binders or fillers. The expanded metal is then incorporated into the sealing materials. The special geometry of the expanded metal produces a three-dimensional-mechanical bond with excellent stress relaxation and recovery of the graphite. Novaphit SSTC has an excellent workability, outstanding thermal and mechanical loading capabilities and exceptional chemical resistance.

Applications requiring high thermal conductivity

Suitable for high pressure and high temperature environments

Excellent gasketing material for sealing high temperature valves, shafts, and flanges

ASTM F 36 J:

Compressibility: 25% - 40% | Recovery: >/= 15%

DIN 3535: Permeability To Gas: </= 1 cm3/min

DIN 28090-2:

Compressibility @ Ambient Temp: 37% - 38% | Recovery @ Ambient Temp: 4%

Creep @ 572F/300C: 1% - 2% | Recovery@ 572F/300C: 4%

DIN 28090S: Specific Leak Rate: .05 mg/s*m

Siemens AV 9-014 - Chloride Content: < 300 ppm

ASTM F 164 (Media Resistance)

@ 302F (150C), for 5h, and ASTM Oil No. 3: Change in Weight: 35% | Change in Thickness: 10%

@ 73F (23C), for 5h, and ASTM Fuel B: Change in Weight: 25% | Change in Thickness: 5%

High thermal conductivity

Impermeable to gases and fluids

Resistant to organic, inorganic acids, solvents, hot wax and oils

Chloric acid and molten alkaline and alkaline earth metals

Strong oxidizing compounds such as concentrated nitric acids, high concentrated sulfuric acids

At 347F/175C: 45 N/mm2

At 572F/300C: 43 N/mm2