Common Applications

- Pumps & Valves

- Ship Ramp Doors (LST, LSD, LCU)

- Hatch Cover, Hatch Seals, Barge Seals, Door Seals

- Container door gaskets

- Marine Commercial Diving for Underwater working - Oxygen Tank Holders & Belts

- Ship Repair - Flanges and pressure containing equipment, including: Exhaust, Steam, Propulsion, and Oil systems

- Deck Rubber Mats

- Rubber Packing Corners and Ends

- Over and Underwater Pipe Repair

Typical Operating Environment

- High & Low Speed Pumps

- Saline, Sea Water

- Temperature variations

- Other elements (sunlight)

- Abrasion resistance

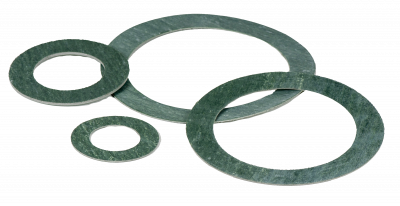

Gaskets

Standard flange gaskets are manufactured to be compatible with ANSI flanges in accordance with dimensional criteria shown in API Standards 601 and 605. A wide range of tooling contributes to our total capability to supply all standard sizes in 125/150 lb., 250/300 lb., ring and full face styles. We are also fully tooled for a specialized range of full face gaskets specified by the Department of Defense for use by the Departments of the Army, Navy, and Air Force.

Materials mentioned in this brochure are a small sample of our inventory, and represent the most commonly ordered materials. Matching PTFE envelopes are also available from stock, adding the flexibility to cope with extremely harsh chemical applications. As a major manufacturer of standard and military flange gaskets, our high speed production methods enable us to supply very competitively priced gaskets in large or small quantities”

Materials mentioned in this brochure are a small sample of our inventory, and represent the most commonly ordered materials. Matching PTFE envelopes are also available from stock, adding the flexibility to cope with extremely harsh chemical applications. As a major manufacturer of standard and military flange gaskets, our high speed production methods enable us to supply very competitively priced gaskets in large or small quantities”

Standard Flange Gaskets - Style: 1015, 1030

Ring Gaskets for 150 lb/300 lb ASME/ANSI Pipe Flanges

Materials:

Style 7100: Compressed Buna-N Nitrile Binder

Style 7237: Red Rubber

Style 7157: EPDM

Style 7075: Frenzelit NOVATEC 825F Engineered Graphite

Style 7085: Frenzelit NOVATEC 925F Engineered Graphite

For other materials and styles, please visit http://www.phelpsgaskets.com/products/gasket-material

Thickness: 1/16” 1/8” Commonly Odered Thickness

Notes: Additional materials and thicknesses available, Available in Various Pipe Sizes, I.D and O.D

Standard Flange Gaskets - Style: 1115, 1130

Full Face Gaskets for 150 lb/300 lb ASME/ANSI Pipe Flanges

Materials:

Style 7100: Compressed Buna-N Nitrile Binder

Style 7237: Red Rubber

Style 7157: EPDM

Style 7075: Frenzelit NOVATEC 825F Engineered Graphite

Style 7085: Frenzelit NOVATEC 925F Engineered Graphite

For other materials and styles, please visit http://www.phelpsgaskets.com/products/gasket-material

Thickness: 1/16” 1/8” Commonly Odered Thickness

Notes: Additional materials and thicknesses available, Available in Various Pipe Sizes, I.D and O.D

Material

An integral element of our exceptional ability to manufacture and supply gaskets, is our extensive inventory of gasket material. At all times we stock a wide range of elastomeric, non-elastomeric, textile, and compressed sheet material in both sheets and rolls.

This, in addition to our stringent quality control program, ensures total consistency of the quality and tolerance accuracy of commercial and specification material alike.

For your convenience, all gasket material is available in whole rolls or cut lengths, sheets, strips of any width and finished gaskets. Materials listed in this brochure are the most commonly ordered in this.

This, in addition to our stringent quality control program, ensures total consistency of the quality and tolerance accuracy of commercial and specification material alike.

For your convenience, all gasket material is available in whole rolls or cut lengths, sheets, strips of any width and finished gaskets. Materials listed in this brochure are the most commonly ordered in this.

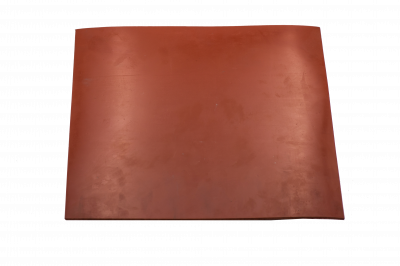

Elastomers - Style: 7237

Red Rubber

An extremely cost effective gasket material suitable for cold and warm water applications. Full rolls, part rolls and sheets are available from stock. Roll lengths vary and should be verified. Sizes other than those shown are available upon request. This material is red in color with a smooth finish. ASTM D 1330.85 Grade 2.

Width: 36”, 48”

Temperature: -20o F/-29o C to 170o F/77o C

Pressure: Minimum 400 PSI, Typical 800 PSI

Durometer: 80A±5

Thickness: 1/16”, 3/32”, 1/8”, 3/16”, 1/4”

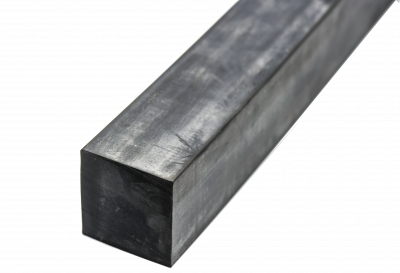

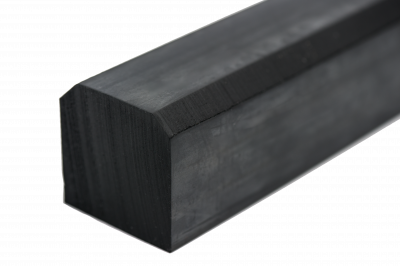

Elastomers - Style: 7104, 7105, 7106, 7107, 7108

Commercial Neoprene

A most economic general purpose material with a wide range of application capabilities. Full rolls, part rolls and sheets are available from stock. Roll lengths vary and should be verified. Sizes and hardnesses other than those shown are available upon request. This material is black in color with a smooth finish. ASTM D 2000 86e, SAE J200 1 BC 510, Mil-R-3065 SC 10.

Width: 36”, 48”

Temperature: -20o F/-29o C to 190o F/88o C

Pressure: 1000 PSI

Durometer: 40A±5, 50A±5, 60A±5, 70A±5, 80A±5

Thickness: 1/32, 1/16”, 1/8”, 3/16”, 1/4”, 5/16”, 3,8”, 1/2”, 5/8”, 3/4”, 1”, 1-1/2”, 2”

Packing

Graphite/ PTFE Packing - Style: 2024

Graphite/PTFE /High Temp Lube/Centerlock

Centerlock® braided from pure CPL fiber. This packing is comparable to GFO® fiber in performance but at a lower cost. CPL fiber is made of: Carbon, a high purity graphite; Polytetrafluroethylene, PTFE; and high temperature inert Lubricant.

This unique packing has a graphite content of over 50%. That means CPL fiber is one of only two yarns to achieve this high graphite content. The end result of this high graphite content is longer wear, better heat transfer, and a broad pH range. Less than 50% PTFE in the yarn makes this packing kinder to the shaft while retaining good abrasion resistance.

This unique packing has a graphite content of over 50%. That means CPL fiber is one of only two yarns to achieve this high graphite content. The end result of this high graphite content is longer wear, better heat transfer, and a broad pH range. Less than 50% PTFE in the yarn makes this packing kinder to the shaft while retaining good abrasion resistance.

Lubricant: High Temperature Inert

Temperature: -400o F/-240o C to 550o F/288o C

Pressure: 5000 PS

FPM: 4912 FPM/25 M/Per Sec

Advantages:

- 2024 is comparable to GFO® fiber in performance but at a lower cost.

- Testing between 2046 and GFO® fibers show equivalent performance.

- Tests include leak rate, heat transfer and elevated temperature yarn shrinkage.

- Best general service high speed pump packing.

- Air, water, sea water, brines, superheated steam, sludges, slurries, waste.

- Petroleum oils, petroleum fuels, solvents, chemicals, liquified gas.

Competitor Equivalent:

- Garlock: Style 5100/EQP2006, PM-6

- Palmetto: Style 1382

- Crane: Style C1065, C1070

- Teadit: Style 210, 2007

Flax & Ramie Packing - Style: 3010

Finest Ramie Fiber

Centerlock® braided from the finest Ramie Fiber. Thoroughly impregnated with PTFE suspensoid and our special marine lubricant. This combination of construction and material provides the ultimate packing for marine rudder post, stabilizer and stern gland service.

Lubricant: PTFE suspensoid and special marine lubricant

Temperature: 260o F/127o C

Pressure: To 1960

FPM: 4912 FPM/25 M/Per Sec

Advantages:Combines a hardwearing fiber with optimum lubricity in the most durable construction. PTFE suspensoid treatment provides superior shaft protection.

Competitor Equivalent:

- Garlock: Style 5413

- Palmetto: Style 1613

- Crane: Style 867

- Teadit: Style 2421

Flax & Ramie Packing - Style: 3014

Flax/Marine Lube/Centerlock

Centerlock Braided from pure high grade Flax. The lubricant is uniformly dispersed throughout the yarn. Before braiding, the rovings are twisted to increase the strength of the finished section and ensures the fibers maintain their integrity.

Lubricant: Quad ingredient compound with minimal animal base

Temperature: 180o F/82o C

FPM: To 1300

Advantages:Our multi-viscosity lubricant affords longer wear and excellent low friction service.

Competitor Equivalent:

- Garlock: Style18

- Palmetto: Style 1600

- Crane: Style 863/863N

- Teadit: Style 2138

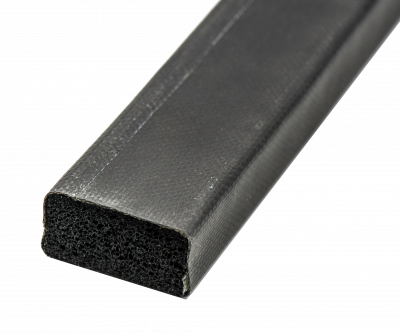

Hatch Seals

Style: 8000 - 8001

Hatch Packing Sponge Core Chamfered

A unique Construction combining the lively properties of an Open Cell Sponge core, completely encased in tough weatherproof jacket of Nylon reinforced Neoprene. The entire section is pressurized to eliminate air during the lamination process, thus ensuring the finished packing maintains its integrity and is not subject to unwanted deformation. Available with or without chamfered edges, this built to specification packing, complete with corners/angles will upgrade or replace most hatch packing styles.

Core: Natural Rubber Open Cell Sponge

Jacket: Nylon inserted Neoprene

Advantages: Open cell core provides more “lively” seal. Complete weather resistance provided by jacket. Excellent longevity.

Style: 8001

Hatch Packing Sponge Core - No Chamfer

A unique Construction combining the lively properties of an Open Cell Sponge core, completely encased in tough weatherproof jacket of Nylon reinforced Neoprene. The entire section is pressurized to eliminate air during the lamination process, thus ensuring the finished packing maintains its integrity and is not subject to unwanted deformation. Available with or without chamfered edges, this built to specification packing, complete with corners/angles will upgrade or replace most hatch packing styles.

Core: Natural Rubber Open Cell Sponge

Jacket: Nylon inserted Neoprene

Advantages: Open cell core provides more “lively” seal. Complete weather resistance provided by jacket. Excellent longevity.

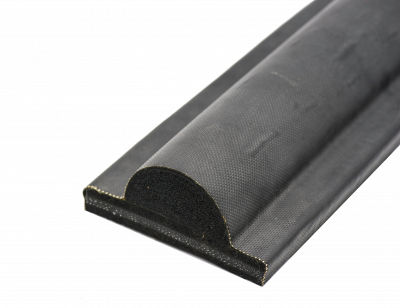

Style: 8200

Ramp Door Gasket - L.S.T., L.S.D., L.C.U.

Extensively used by the United States Navy and Coast Guard as a landing craft ramp door gasket. Utilizing similar material to Styles 8000 and 8001 hatch packing, an additional 1/4” thick layer of Cloth Inserted Rubber laminated into the open cell platform provides a very sturdy base. The dome of Open Cell Sponge creates a lively sealing area, and the entire section is completely weatherproofed by a tough Nylon inserted Neoprene jacket.

Dome: Natural Rubber Open Cell Sponge

Jacket: Nylon inserted Neoprene

Advantages: The combination of materials provides a very sturdy base with a “lively” dome seal. Long-lasting and weather resistant. Reinforced jacket resists tears and abrasion.

Style: 8010

Hatch Packing Solid Rubber Core Chamfered

Homogenous rubber hatch packings are constructed from special media, salt and weather resisting compounds. Special ordered compounds have no dimensional limitations. The following material is suggested as primary compounds for Styles 8010.

Materials: Neoprene, Ethylene Propylene, Buna-N

Temperature: -20°F/-29° to 170°F/77°C

Advantages: Good resistance to salt water, weather, ultra-violet, ozone, moderate oil resistance. Excellent resistance to salt water, weather, ultra-violet, ozone, oils and solvents, ester based fluid, alcohol

Style: 8011

Hatch Packing Solid Rubber Core - No Chamfer

Homogenous rubber hatch packings are constructed from special media, salt and weather resisting compounds. Special ordered compounds have no dimensional limitations. The following material is suggested as primary compounds for Styles 8010.

Materials: Neoprene, Ethylene Propylene, Buna-N

Temperature: -20°F/-29° to 170°F/77°C

Advantages: Good resistance to salt water, weather, ultra-violet, ozone, moderate oil resistance. Excellent resistance to salt water, weather, ultra-violet, ozone, oils and solvents, ester based fluid, alcohol

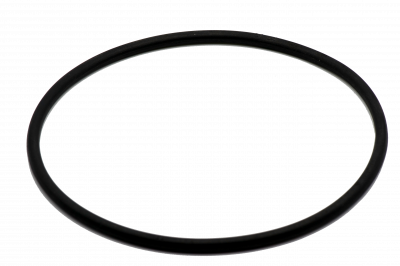

‘O’ Rings, Molded Parts

Custom & Standard O-Rings

Standard ‘O’ Ring Compounds

A full range of quality ‘O’ rings are available in commercial and military specification material. In addition to the American Standard AS series, non-standard requirements can be accommodated by either vulcanizing from close tolerance ‘O’ ring cord or choosing from a wide availability of metric sizes.

Standard Compounds : PB70, PE70, PN70, PV75, PS70, PF70, PTFE

Standard Compounds : PB70, PE70, PN70, PV75, PS70, PF70, PTFE

PB70

Polymer Type: Buna N, Nitrile

ASTM Designation: BF, BG, BK, SB, SA, NBR

Typical Properties: -40oF/-40oC to 275oF/135oC General purpose compound. Excellent resistance to petroleum base lubricants, hydraulic oils, gasoline, fuel oil, alcohol, water, and L.P. gas.

PS70

Polymer Type: Silicone

ASTM Designation: FC, FE, GE, TA

Typical Properties: -80oF/-62oC to 450oF/232oC Hot air, weather, oxygen, ozone, excellent for medical applications, moderate chemical resistance, various fluids.

PE70

Polymer Type: Ethylene Propylene

ASTM Designation: CA, R(s), EPDM, EPR

Typical Properties: -67oF/-55oC to 300oF/148oC Animal and vegetable oils, oxygen, ozone, hot water, steam, mild acids, ester based fluids, alcohol.

PF70

Polymer Type: Fluorosilicone

ASTM Designation: FK, TA, TB, FVS

Typical Properties: -70oF/-57oC to 350oF/177oC Combines excellent oil and chemical resistance with wide temperature range.

PN70

Polymer Type: Neoprene, Chloroprene

ASTM Designation: BC, BE, SC, CR

Typical Properties: -50oF/-46oC to 275oF/135oC Oxygen, ozone, weather, chlorine, freon gas, carbon dioxide.

PTFE

Polymer Type: Polytetro Fluoroethylene

ASTM Designation: PTFE, TFE

Typical Properties: -400oF/-205oC to 550oF/287oC Excellent resistance to all chemicals and solvents. Very low coefficient of friction.

PV75

Polymer Type: Viton®, Fluorocarbon

ASTM Designation: HK, TB, FPM

Typical Properties: -30oF/-34oC to 425oF/218oC Excellent high temperature resistance to animal and vegetable oils, acids, alkalis, fuel oil, gases, wide range of other fluids and chemicals.